SSAB is entering a partnership with EAB for the supply of fossil-free steel, including SSAB Zero™, for use in EAB's core businesses: warehouse fittings, doors, and steel buildings.

"We are pleased to deepen our cooperation with EAB, which has already started using SSAB Zero™ in its production. This shows that fossil freedom is not just a vision but a reality, making a difference here and now. Together, we are taking concrete steps to reduce climate impact and create sustainable solutions for the industry", says Thomas Hörnfeldt, Vice President Sustainability, SSAB.

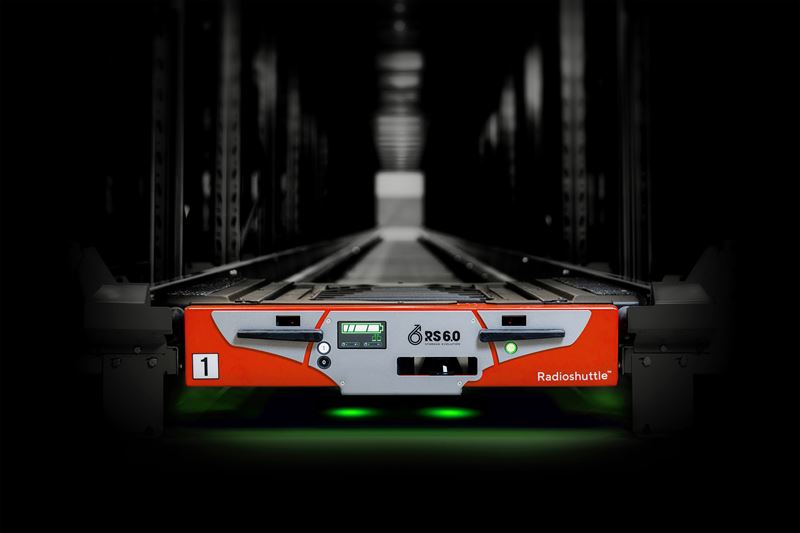

EAB has already implemented SSAB Zero™ in the machine chassis of Radioshuttle™, EAB's flagship product in warehouse management and the system that has made EAB successful, particularly in international markets. Radioshuttle™ is designed to optimize customers' storage space and reduce energy use.

"The partnership with SSAB demonstrates our commitment to continue driving development forward - a shared promise of how we will take steel into the future. This journey is not one you make alone. We do it together", says Per-Åke Andersson, CEO, EAB Group.

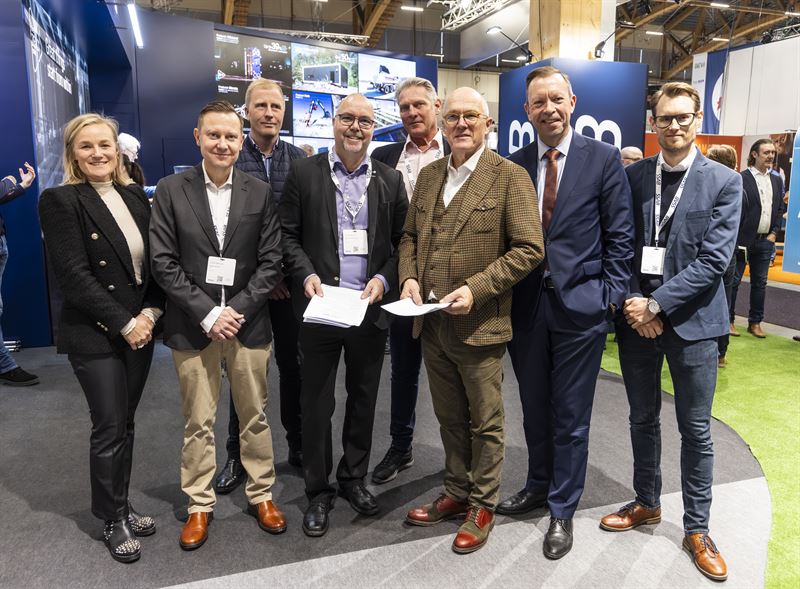

SSAB och EAB signing partnership. Front: Kajsa Andersson, EAB, Matts Nilsson, SSAB, Thomas Pettersson, SSAB,

Per-Åke Andersson, EAB, Thomas Hörnfeldt, SSAB and Nicklas Nilja, SSAB. Back: Mats Ekberg, SSAB and Peter Jähnke, SSAB

EAB is a company with extensive experience in developing, manufacturing, and installing warehouse fittings, doors, and steel buildings-always with a focus on quality, functionality, and long lifespan. The company is headquartered in Smålandsstenar, Sweden, but its products are used globally. Sustainability is a central part of its operations and means designing solutions that stand the test of time. EAB aims to halve its carbon emissions within ten years and has already taken important steps through its own solar park, sustainable transport, and now climate-improved steel.

Traditional steelmaking is a significant source of global CO₂ emissions. By changing how steel is produced, SSAB aims to reduce emissions and create fossil-free value chains together with customers and partners.

- SSAB Zero™ - Based on recycled steel and produced using fossil-free energy. Quality and properties match SSAB's conventional steel. Commercially available since 2023.

- SSAB Fossil-free™ steel - The world's first fossil-free steel in the form of proof-of-concept and pilot deliveries. Using hydrogen-reduced iron ore according to HYBRIT® technology eliminates the primary source of CO₂ emissions in steelmaking, so the process emits water instead of CO₂. The first exclusive volumes have been delivered to key customers for use in trucks, dumpers, car seats, and watches. The next step is scaling up to industrial level for commercial volumes.

For further information, please contact:

Charlotte Lindevall, Head of External Communications, charlotte.lindevall@ssab.com, +4670 344 59 73